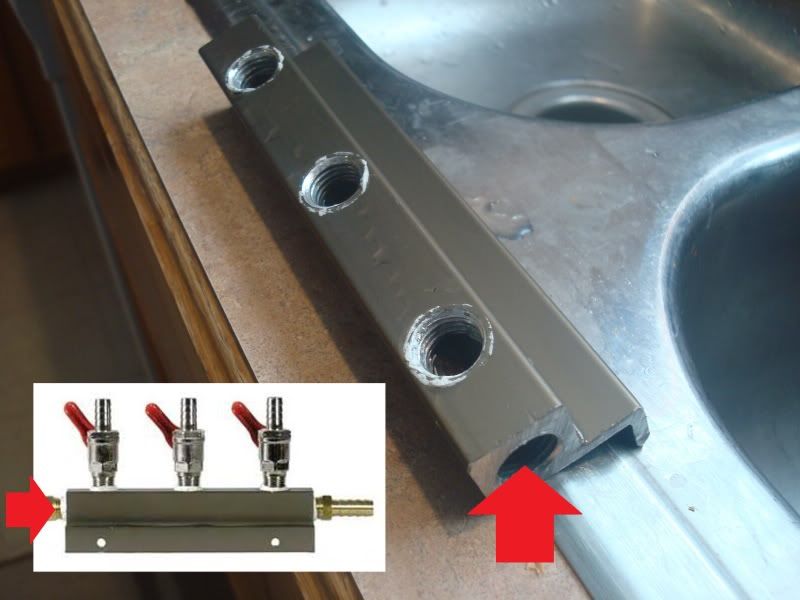

I had a beer turn off really sour after a long storage for no apparent reason. The only thing that came into contact with this beer during storage was my three way gas splitter. It may have gotten some beer back flow when I moved some kegs around especially because I carb from the bottom up. The photo shows it after I took the ball values off but for reference there's a new model in the corner and the arrows point to the same end.

I haven't used this splitter in about 4 months so I figured I'd run some hot water through it just for good measure maybe knock some dust out. When I ran the hot (from the tap) water through it I noticed little bit of stuff coming out of the lines. So I got beer line cleaning gear out and ran some hot Beer Line Cleaner "BLC" through it, because I hadn't taken it apart yet. Yes I did run all the liquids in the same direction as gas would flow because of the check values in the ball valves.

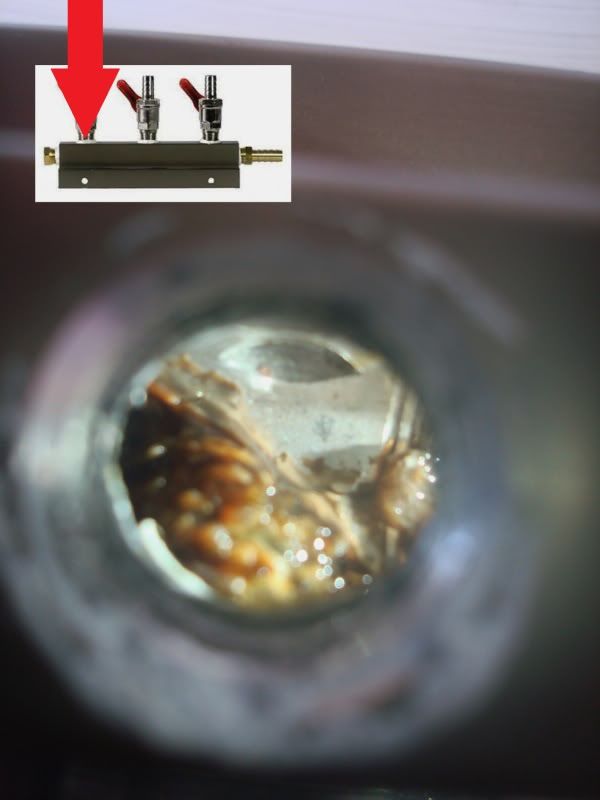

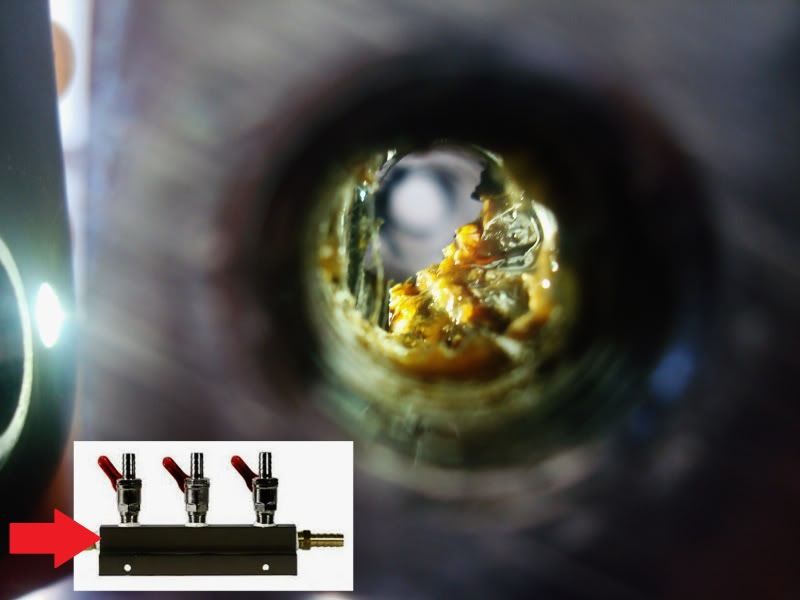

After 2 quarts of BLC through each port I flushed the whole thing with 5 gallons of hot water, ran just enough Star-San to get through everything, and finished it off with a flush of CO2 from the 20# tank set at 30 PSI. I then set the whole thing out in the sun to dry. I noticed that the flow rates for each port was different until I worked the valves a bit. I figured it was just freeing up any crud the may be trapped in there. When I picked it back up for some reason I wanted to check that everything was clear so I attempted to blow air through the lines by month (don't ask me why I did this after already running StarSan). Good thing I did because I could not get anything through the first port. I then took the thing completely apart. This is what I found. The arrow is pointing to where the picture was taken from.

I tried to disassemble the ball values to see if I could clean them up however there are some parts that are pressed into place. So this whole thing is scraped and I'll be getting a new one.

Moral of the story is, just because the ball values have a one-way inside them doesn't mean they work well. Be extra careful if you carb from the bottom up. (That means you have gas going in the keg through the liquid-out side.) The best way to prevent this type of thing from happening to you is making sure that EVERY TIME, even if your hooking up for serving, you add a new keg to the splitter or change the pressure from the regulator you follow the bellow procedure.

Adding a new keg

1. Pull the value on the lid to completely de-pressurize the keg. (For you pin heads out there you can push down on the center of the gas post or attach a gas disconnect that isn't attached to any tubing.)

2. Make sure the gas is flowing all the way to the disconnect (in case there's more then only value in the line from regulator to the disconnect)

3. Attach your keg

Changing the pressure of the regulator (especially if you decrease the PSI)

1. Disconnect each keg.

2. Change your PSI.

3. Bleed the lines. ( It helps insure your PSI change is accurate, I do this by unscrewing the disconnect a little.)

4. Adjust PSI if necessary

5. Then follow the steps for adding a new keg.

Remember to check on your system if it changes temperature. If your kegs are going from cold to warm the PSI inside the keg will increase to the point where it could over power the PSI set by the regulator. Also if your regulator goes from cold to warm it could decrease the PSI of the set point and cause the same issue.